XYLEM X4

WORLD’S FASTEST VAPE CART FILLING MACHINE

-

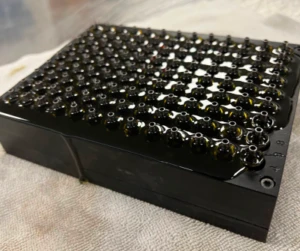

Speed:1650 units/hour

-

Form Factor:All 510 top-filled vape carts with press, screw, or click-in closures

-

Fill Material:All liquid concentrates

-

Low Temp Filling:Fill at temperatures as low as 45° C

-

Fully Automated:In-line fills and caps immediately to preserve terpenes

-

Personnel:1 technician

INCREASE SPEED, SCALE, & QUALITY

The Xylem X4 fully automates cart filling and capping, greatly simplifying the vaporizer manufacturing process. Xylem is the fastest cart filling system on the market, delivering an unparalleled product for your consumers.

UNMATCHED SPEED & EFFICIENCY

One X4 machine is capable of delivering the output equivalent to 20 workers at a fraction of the cost. The Xylem X4 cart filling machine is the best solution on the market for cannabis manufacturers.

HOW IT WORKS

SCALE UP THROUGH TECHNOLOGY

DECREASE YOUR COST PER UNIT

REALLOCATE STAFF ALONG THE MANUFACTURING LINE

MOST OPERATORS GENERATE A RETURN ON INVESTMENT IN AS LITTLE AS TWO MONTHS

DON’T COMPROMISE QUALITY

MORE ACCURATE FILL LINES THAN ANY OTHER METHOD

MINIMIZE VAPE CART LEAKS AND TRANSFER LOSS

-

Instantaneous capping locks in high fill lines. This is a game-changer for the consumer experience when seeing the product on dispensary shelves.

-

Ability to fill at lower temps, which preserves terpenes and decreases product degradation.

-

Capping vapes one at a time with precision alignment ensures strong vacuum lock to eliminate leaks.

-

Argon or Nitrogen overlay prevents oxidation while preserving flavor and color of oil.

INDUSTRY LEADING SUPPORT

Xylem’s best-in-class support services are available for your team every step of the way. Whether your team needs quick troubleshooting support via video chat or on-site service, Xylem delivers superior expertise to support the growth and success of your business.

LEARN HOW WE HELP OUR CLIENTS

THIS STREAMLINES EVERYTHING

-DREW FORD CSO KASE MANUFACTURING

TRUSTED BY INDUSTRY LEADERS

EXPLORE OUR CONTENT

FAQ

All 510 thread top filled vape carts with any type of closure press, screw, or click.

6 weeks on order.

Yes – Xylem X4 can be sterilized and all resin is sealed until injected into the cartridge.

Yes – we offer both live in person and video demos. Customers can run the system with their carts and vape formulation if desired before purchasing.

All liquid concentrates: Pressed Rosin, Live Resin, Distillate, Sauce, CBD, D9, D8, D10, and HHC.

1,650 filed and capped vapes per hour with 1 trained operator.

We provide on-site availability for addressing issues, with most problems resolved through our 24/7 live video chat service. Additionally, we offer advanced training for operators at either your facility or our locations in Houston.

0.25% weight deviation

SPECIFICATIONS

Performance

| Run Speed | 1300-1650 units/hour |

| Temperature Range | 45°C - 75°C (86°F - 167°F) |

| Distillate Compatibility | D9, D8, & CBD(Liquid) |

| Resin Compatibility | Liquid Live Resin |

| Rosin Compatibility | Liquid Rosin |

| Cartridge Compatibility | Press, Click, & Screw |

| Wetted Materials (Pump, Line) | Ceramic, 316 Stainless Steel |

Dimensions

| Height | 71 in |

| Length | 43 in |

| Depth | 31 in |

| System Weight | 950 lbs* |

| Oil Tank | 2 liters |

| Extendable Working Bench | 9 x 48 in |

| Floor Grade | <1 degree |

Utilities / Environment

| Input Power | 115-120V, 10A Max |

| Input Air PSI | 80psi @ 4.5CFM |

| Environment Temperature | 65°F - 85°F (18°C - 29°C) |

| Operating Environment | In-door lab / GMP |

| Working Space | 10ft x 10ft |

| Sterilization | FDA/GMP Process Compatible |

| PPE Requirements | GMP Standard |