Glass cartridges and ceramics are known for weight deviations of over 0.6 grams, making it very difficult to weigh out dosed extracts in a manufacturing line. Zeroing every cartridge on an analytical scale is impractical, so a statistical deviation method is implemented below to determine extract weight during manufacturing and compliance reporting.

Fill 50 cartridges, then subtract the weight of 50 empty cartridges (with mouthpieces), and divide the weight by 50 to determine the weight per cartridge.

- Minimum cartridge count for weight check: 20 filled cartridges

- High confidence cartridge count for weight accuracy: 50 filled cartridges

- 2X+ standard deviation cartridge count for weight accuracy: 100 filled cartridges

Definitions

-

- Analytical Scale – high precision scale for single cartridges with an accuracy of 0.0001 grams

- Industrial / lab standard Scale – Scale used for industrial and labs with 0.1 gram accuracy

Food Scale – usually a home-use device not recommended for compliance with weighing

Scale Precautions

- ⛔️ Always make sure you have a centered scale and a flat working surface – having an off-centered scale risks major systemic inaccuracy. ⛔️

Causes of Cartridge Weight Variance

Manufacturing materials and process

“Glass” – when being shaped into a cart tank is hot is a pliable flowing material that is difficult to control

“Ceramics” – while shaping ceramics is easy, the glazing and finishing steps add many weight variables that are difficult to control due to the spray process

“Tolerance controls” – manufacturing control on tolerance has impacts on weight.

Cartridge Weighing Instructions

Step 1: Weigh unfilled carts

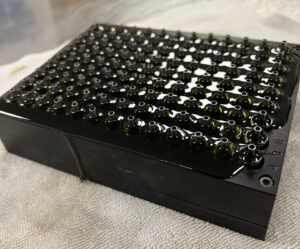

Place 50 (20 or 100) unfilled cartridges and mouthpieces on a scale and record the weight.

Step 2: Fill carts

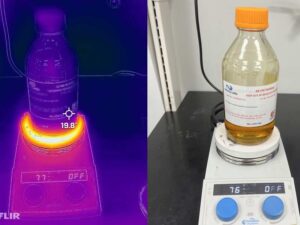

Fill 50 (20 or 100) cartridges with extract and record the weight.

Step 3: Subtract the unfilled weight from the filled weight to determine the total weight of the extract. Then, divide the extract weight by the number of carts to get the weight per cartridge.

Why 20, 50, 100 Cartridges?

The standard deviation of glass cartridges generally is between 0.2 – 0.3 grams. 20 cartridges average in weight close to the mean with acceptable variation similar to plastic cartridges. 50 cartridges is close to capturing 1 standard deviation of weights depending on the sample which is accurate for weight. 100 cartridges capture sufficiently 2X+ standard deviations of cartridge weights and is a highly reliable degree of weight confidence.

Caveats

Blended batches of carts from different manufacturing batches will negatively impact variance. If using a blended cartridge batch, it is best to double all weight-out numbers to 40, 100, and 200 to account for even wider variations in vape cart weight.