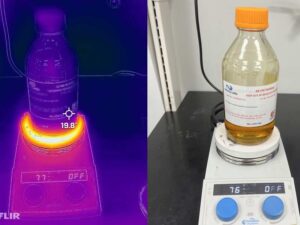

Automating live resin filling is one of the most difficult processes in vaporizer cartridge filling. Not only is the resin notoriously temperature and oxygen-sensitive, but the filling process is also often a point of failure due to the wide range of equipment the resin makes contact with. During filling, live resin is subject to conditions that need to be controlled perfectly–including heat exposure, aggressive agitation, and oxygen–all of which can degrade terpenes and distort flavor by creating unwanted side reactions. This article will cover the difficulties of handling live resin and also the solutions developed by Xylem to address these difficulties head-on.