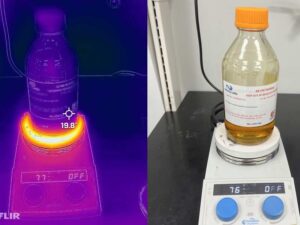

Another thing is to restrict the quantity of ethanol so you aren’t leaving large concentrations in the open during the organic synthesis of products from reactants. This includes the oxidation, dehydration, substitution, pH detection, and esterification of alkoxides.

In Section 2 of the MSDS, the hazard identification classifies ethanol as:

Category 2 for flammable liquids, reproductive, and organ toxicity

Category 3 for irritation from oral, dermal, and inhalation

That’s why ethanol is capable of reacting violently with many kinds of mixtures. For example, you should never combine it with concentrated sulfuric acid or hydrogen peroxide because it could yield an explosive release of energy and damage the surrounding equipment.

With that in mind, you’ll need to take preventive measures against dangerous incidents such as a fire in the building. Therefore, you have to account for static discharge or lighting by making all materials explosion-proof.

To clean up an ethanol spillage, try collecting it with an electrically insulated vacuum cleaner. For smaller amounts, use a wet brush to soak up the contents and seal them in a disposable container.

Once you are done, store it in a closed cabinet and away from reactive chemicals including oxidizing agents, strong acids, and bases. Have the safety data sheet on hand if you ever encounter an emergency and need to take first-aid or fire-fighting measures.

According to standard practices, all lab personnel must be able to locate emergency equipment. This includes the fire extinguisher, fire alarm, eyewash station, and standing shower.