Reclaiming Oil Concentrates from Cannabis Waste

Properly implementing the recapture of “waste” concentrates like resin or distillate on glassware, tools, wipes, and equipment can lead to many saved kilograms of material each year. This guide to recovering and recapturing cannabis waste covers the main processes for reclaiming oil concentrates in cannabis manufacturing — keep in mind that additional methods and solvents are available beyond the proposed solvents, and some processes require a Class 1 Division 1 (C1D1) environment to function, and state laws restrict the use of some solvents.

Cannabis Waste Falls Into Three Categories:

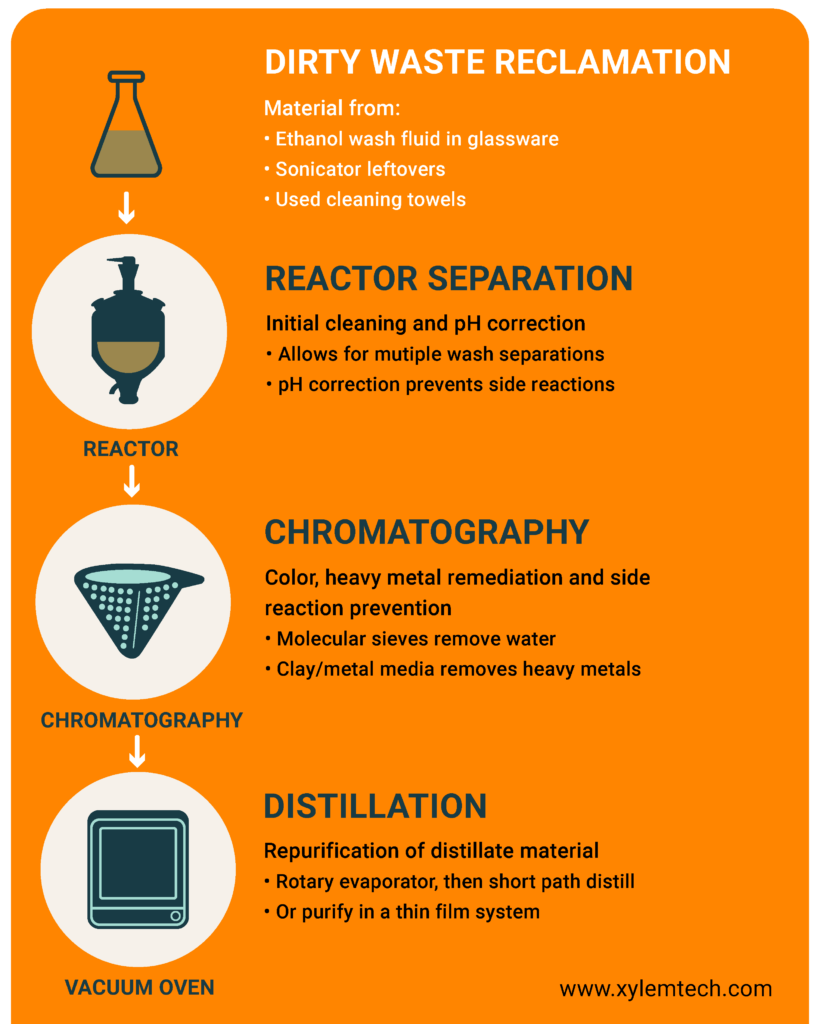

- 1. “Dirty” refers to material mixed with hydrocarbon solvents like ethanol or isopropanol or a caustic cleaning agent like industrial purple.

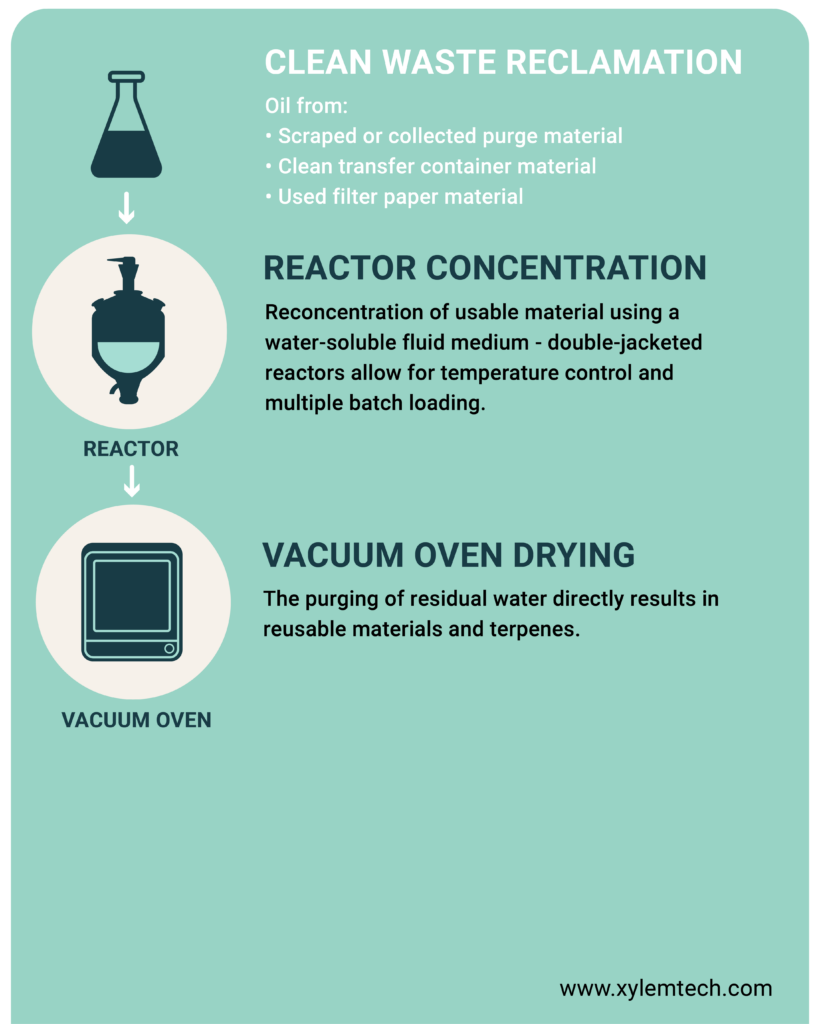

- 2. “Clean” indicates that the material can be reused — examples include fresh jar scrapings, tool coatings, and machine-purged material.

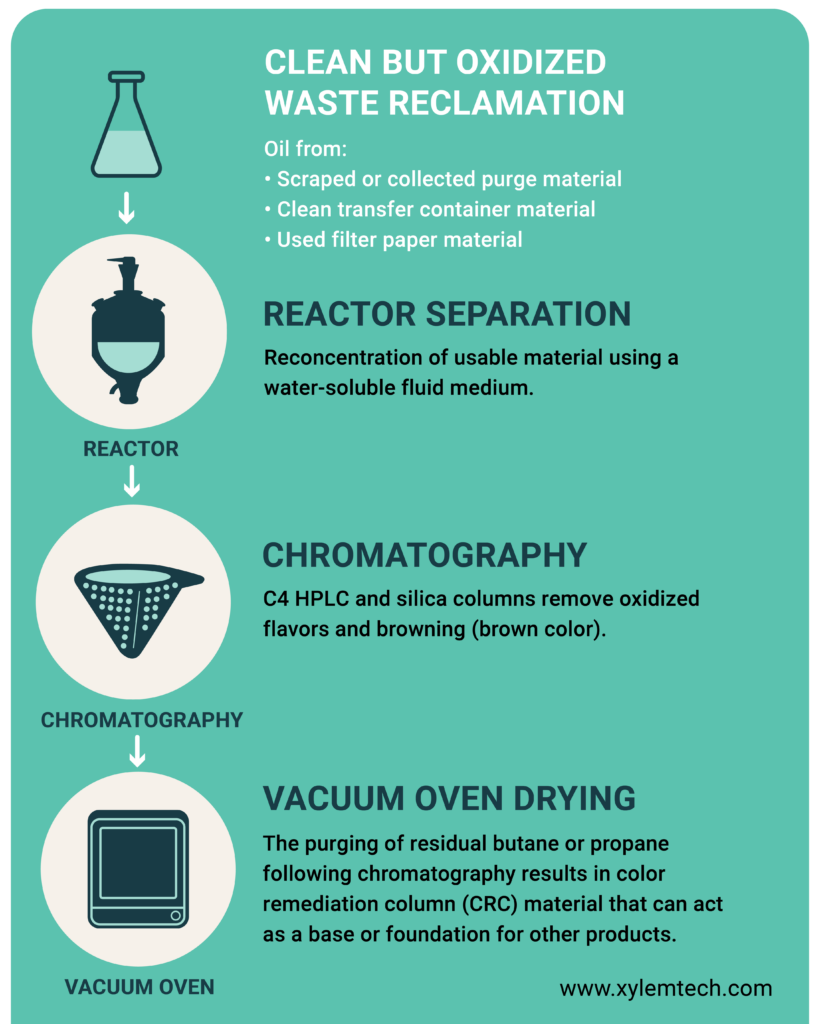

- 3. “Clean but oxidized material” applies to old material that can be reused but has developed off-putting flavors — examples include filter paper from a rosin press, activated/denatured live resin from overheating, oil exposed to activated media, and machine-purged material left in open containers for months.