XYLEM Y2

FULLY AUTOMATED PRE-ROLL INFUSION MACHINE

$45,000

-

Speed:500-700 units/hour

-

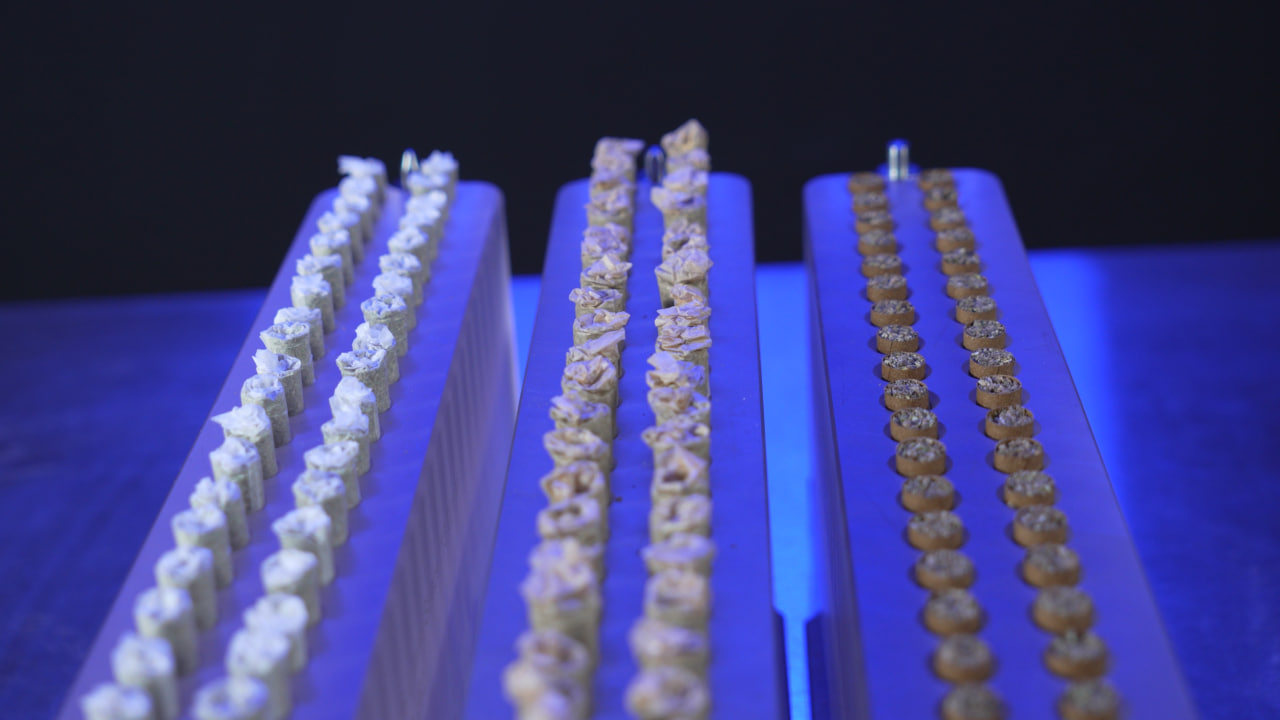

Pre-Roll Type:Paper cones, straight rolled tubes, blunt wraps, and other form factors

-

Fill Material:Any liquifiable concentrates: rosin, live resin, distillate, sauce, CBD, D8, or HHC

-

Low Temp Filling:Fill at temperatures as low as 35° C

-

Infusion Types:Donut joints and hash holes

-

Personnel:One technician

The Y2 - 40 TIMES FASTER THAN HAND INFUSING

The Xylem Y2 is the most advanced and cost effective pre-roll infuser on the market. This system automates the labor-intensive task of infusing pre-rolls with any type of liquefiable resin and concentrate, enabling operators to make high-value infused donut joints and hash holes. The Y2 is GMP ready with a full safety enclosure and wipe down capability - purpose-built to operate in ISO classification clean room environments. This system utilizes precision pumping and temperature control to deposit a highly accurate line of resin inside the pre-roll; it is capable of producing 500-700 infused pre-rolls per hour. The Xylem Y2 Automated Pre-Roll Infusion Machine manufactures infused pre-rolls with perfect accuracy, with a consistent resin to flower ratio.

LIVE RESIN, ROSIN, AND DISTILLATE COMPATIBLE

PRECISION CONTROLLED HEATED LINES & NEEDLES

HIGH ACCURACY CERAMIC PUMP

LOW TEMPERATURE ROSIN COMPATIBLE

Y2 PERFORMANCE

The Y2 is the most precise dosing pump for gelled resins and has the lowest operating temperature of any system on the market - preserving the most difficult high-value resins, including live rosin, live resin, batter, as well as distillate. The Y2 is purpose-built for cannabis resins and terpenes. All material contact surfaces from the tank to the pre-roll are stainless steel or ceramic to ensure both system durability and material integrity.

Y2 FLEXIBILITY

Y2 delivers on-demand infused pre-roll manufacturing capability and adapts to any type of pre-roll form factor. Simple tray parts and self serviceability allows for high operating uptime from operating staff. Enclosed system design, casters and easy utilities allow manufacturing anywhere on the factory floor.

FAQ

Yes, the Y2 can infuse any pre-roll to create perfect donut joints or hash holes.

Each tray is custom made to accommodate any pre-roll shape, size, diameter, and length.

Yes, the Y2 can even infuse partially decarbed rosin and live resin and rosin jelly.

Paper cones, cigarette style, glass tips, straight rolled tubes, and blunt wraps, and other form factors.

Any type of liquid concentrates: Rosin, Live Resin, Distillate, Sauce, CBD, D8, or HHC.

The current lead time is 6 weeks.

SPECIFICATIONS

Dimensions

| Height | 57.87 in |

| Length | 32.28 in |

| Depth | 22.24 in |

| System Weight | 350 lbs |

| Oil Tank | 1 liter |

| Max Pre-Roll Length | 120 mm |

| Min Pre-Roll Length | 40 mm |

Performance

| Run Speed | 500-700 units/hour |

| Temperature Range | 35°C - 95°C (95°F - 203°F) |

| Distillate Compatibility | D9, D8, & CBD (Liquid), HHC |

| Resin Compatibility | Live Resin / Melted Slabs / Liquefied Batter |

| Rosin Compatibility | Liquefied Rosin |

| Pre-Roll Closure | Open, Twist, or Dutch Crown |

| Pump Material, Lines | Ceramic, 316 Stainless Steel |

Power / Utilities

| Input Power | 110V, 8A Max |

| Input Air PSI | 70-80psi @ 2.3CFM |

| Environment Temperature | 65°F - 85°F (18°C - 29°C) |

| Operating Environment | In-door lab or GMP |

| Recommended Working Space | 5ft x 5ft |

| GMP Disinfection & Clean | Yes |

| PPE Requirements | Full GMP Standards |