Extracting the best ROI out of your cannabis crop for the Best Return on Investment – Cannabis Company Perspective:

Introduction:

While Xylem makes some of the most efficient cartridge-filling machines and preroll infusion systems on the market manufacturing efficacy is only a portion of the puzzle on how to make money in the cannabis industry. I speak to a lot of owners and executives from large MSOs to family companies and the discussions are all the same around how to maximize profitability.

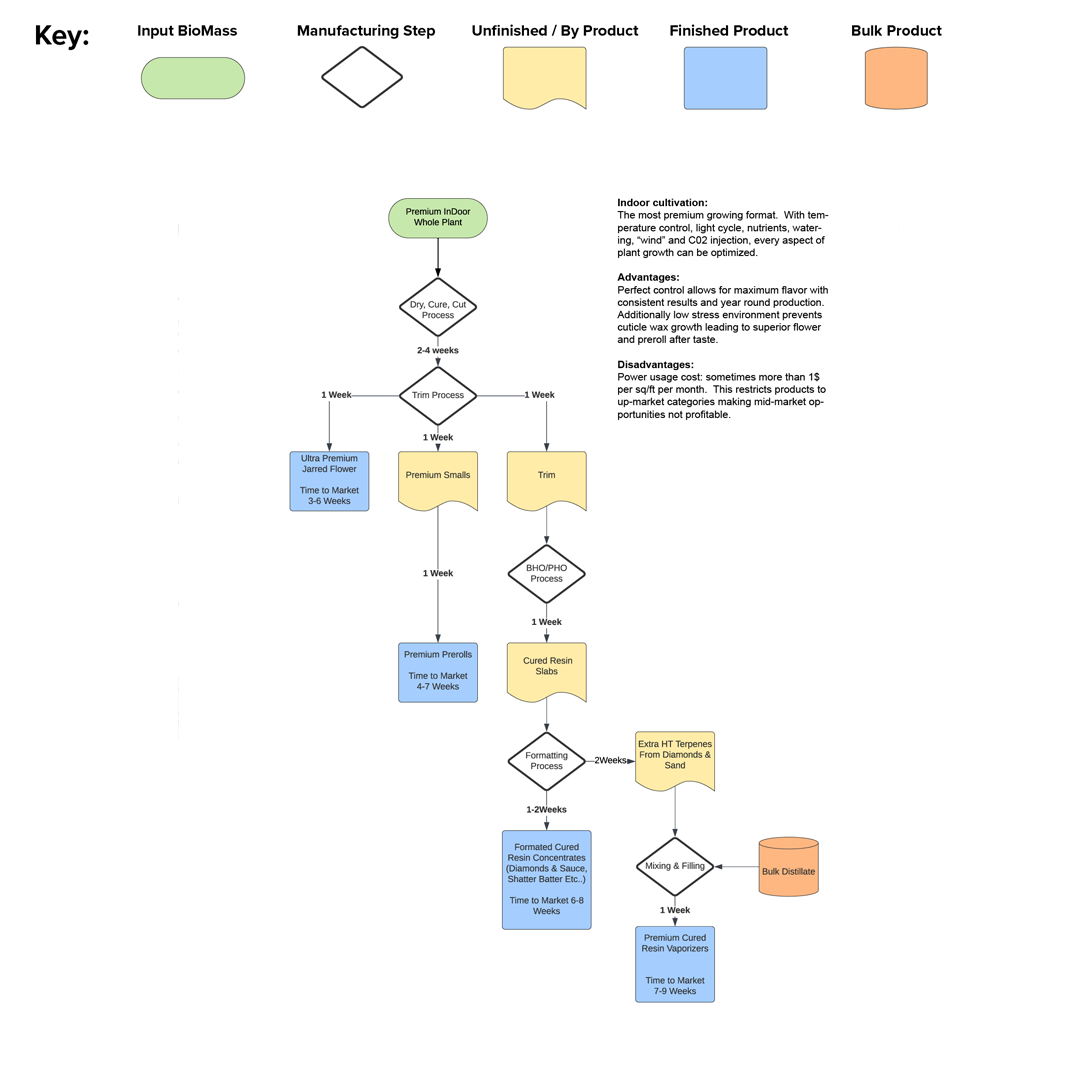

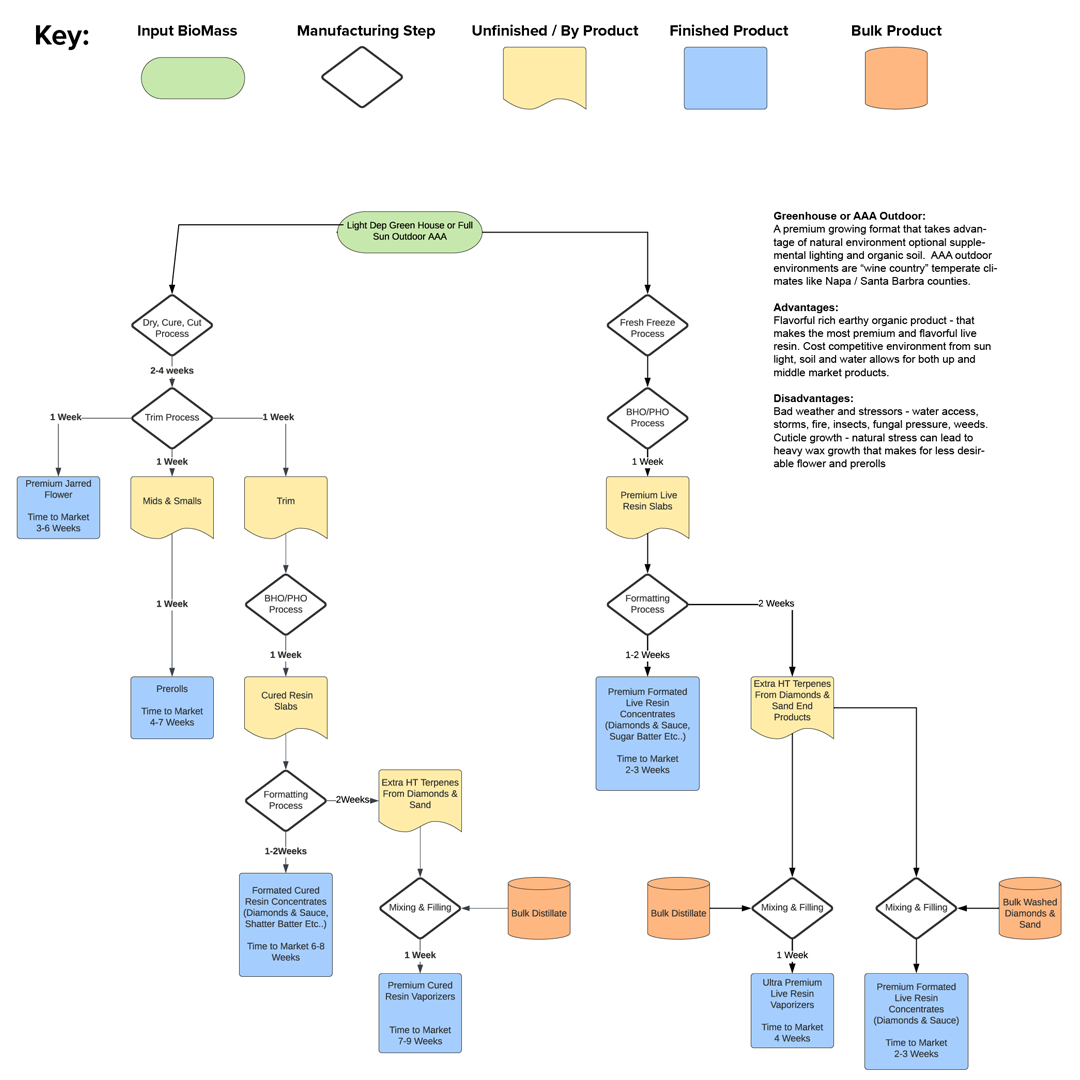

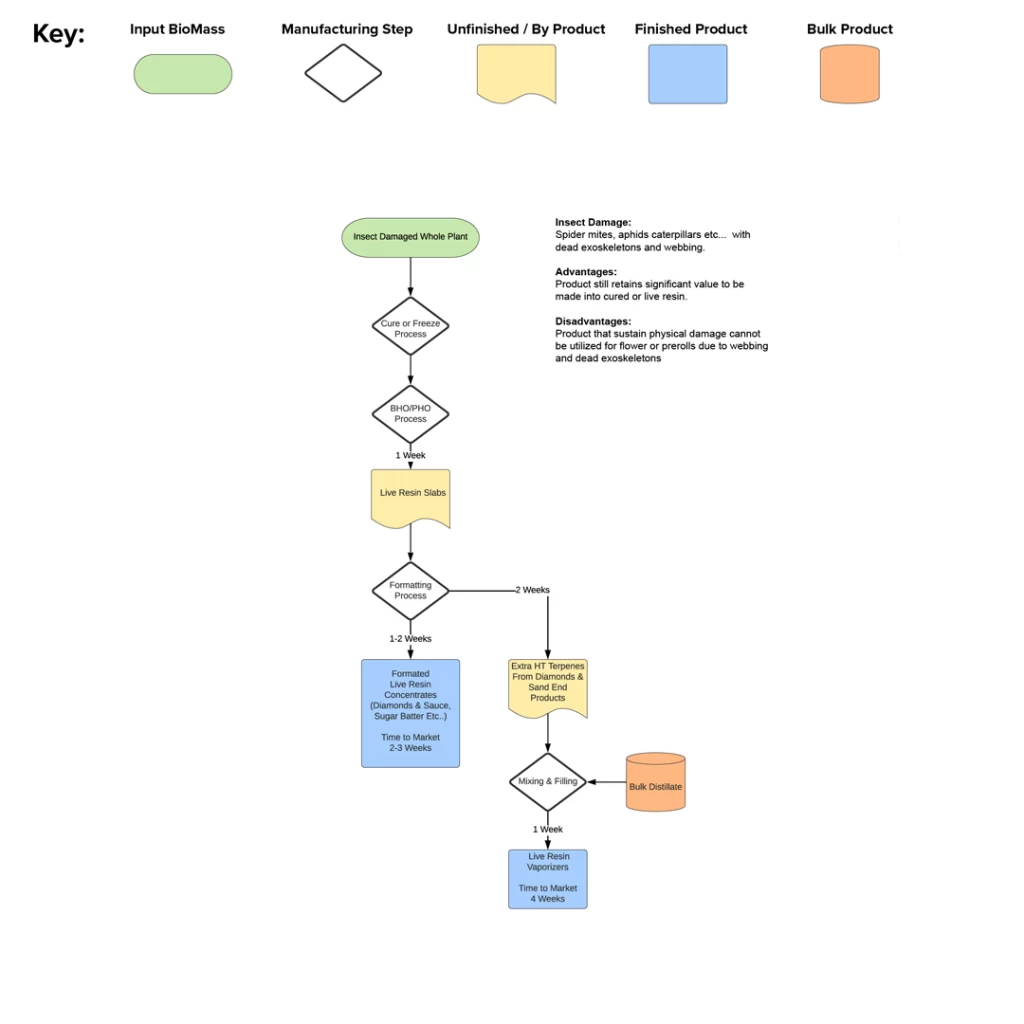

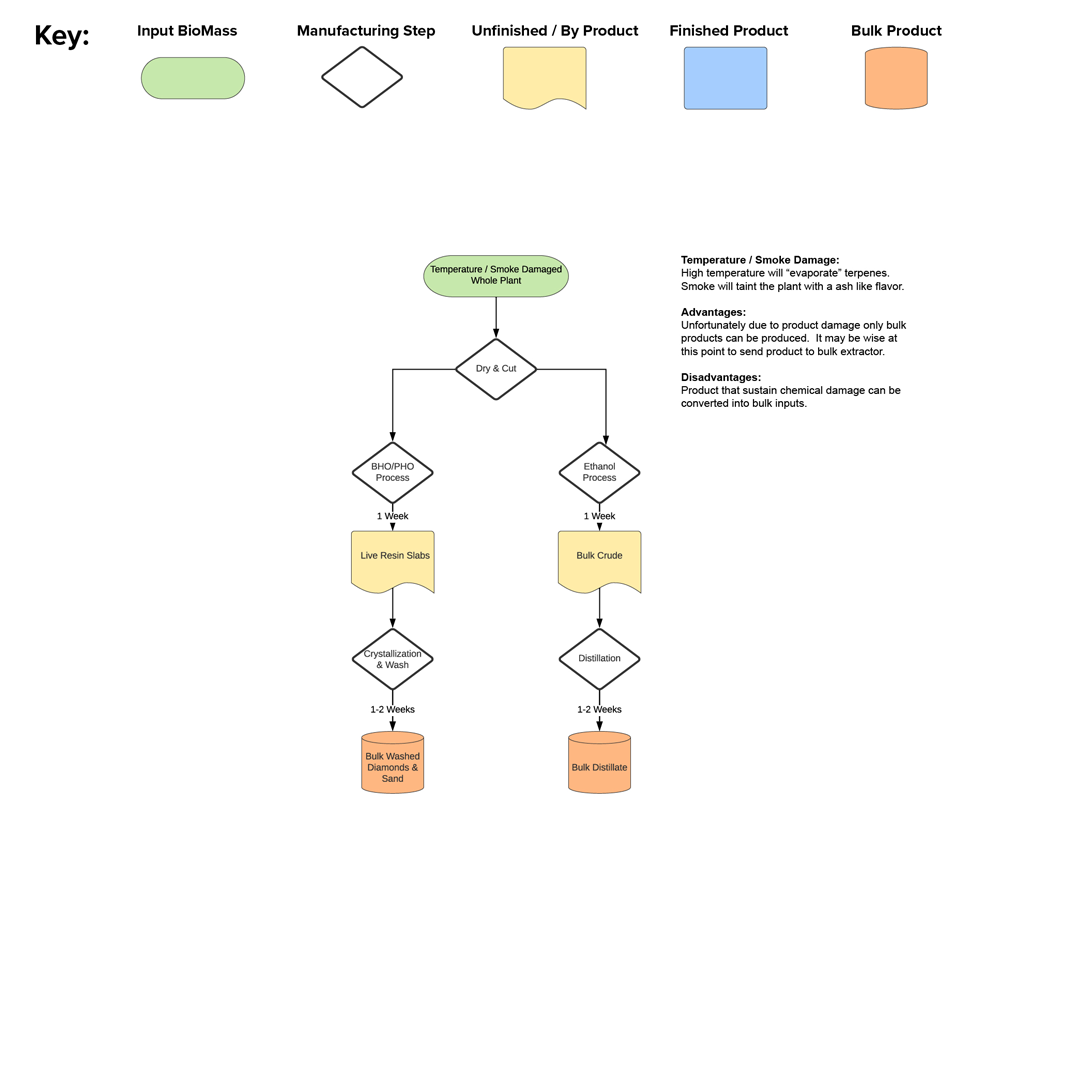

I have put together a flow chart of the flow from the plant to each type of product and the intersection of time & effort (manufacturing steps) for maximum profitability and the easy ways you can mix and recombine products to achieve the most value (expensive) products.

This article will not talk about cannabis marketing/branding perceptions but actual utility value that can be derived from an input –flower, fresh frozen, or trimmed. This article also will not cover more advanced recombination techniques of products like, cold pressing rosin, infusing prerolls, or using selective CRC chromatography to selectively remove certain flavors out of BHO resin. While these are all very valid and useful techniques for a business, we are taking a farm-to-table approach on how to maximize margins – so someone does not turn an indoor flower into a distillate vape and leave tons of margin on the table.

Definitions:

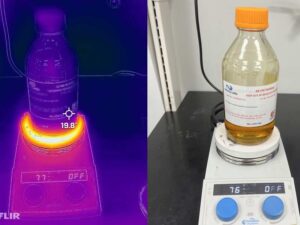

“Slabs:” – in this context means undifferentiated resin from a BHO system – it doesn’t mean pure taffy-like slabs per se; it can mean partly crystalized batter or unformatted material coming out of a BHO extraction system like the Luna Extractor, BizzyBee or Precision Extraction system.

Time to Market: this is what I typically saw at least in California – while the process can be sped up significantly on the vape cart filling side due to us not so much on the curing size for flowers that need time to dry and age with real no effective to accelerate this process.

Extra HT Terpenes: This assumes you are in a state like California and not Oregon which allows for full remixing of terpenes from one batch to another. In some states, this is not possible so this remixing process would not be workable.

Premium in Door Whole Plant:

At the top end of the pricing spectrum, nothing can beat indoor grows that are well managed with care and craftsmanship. Crafted premium hand-selected and trimmed flower are the best with good reason: grown in a perfectly controlled environment free of insects and fungi. The fastest way to get to a product is to sell jarred flower with smalls and damaged flower getting turned into pre-rolls. The trim & kief, however, if not used in infused products can be used for extraction usually into a premium cured resin which can be reformatted into dabs or cure resin pens.

Power and labor costs, however, will be one of the biggest cost drivers which necessitates the need for premium prices.

Side note: Live Resin vs Cured Resin is like arguing red wine vs white wine. There is one difference I have noticed is that Cured Resin tends to maintain coloration longer than Live Resin which can be advantageous for storage and dispensary shelf-life.

Light Dep Green House / Full Sun Outdoor (Napa/Santa Barbara Climate):

Light-deprivation greenhouses and full-sun outdoor cannabis are some of the less costly methods to produce cannabis. Both of these methods use natural sunlight and many users prefer the organic earthy flavors of plants grown in soil vs hydroponics. Flower grown under this method will have thicker wax cuticles and will have a different mouthfeel from indoor flower.

Due to the thick cuticles, flower from this type of growth will not be able to command as high as a premium. Also, insect damage and the weather can render a crop unusable for flower or prerolls.

However, if the crop is frozen or cured, the results will be a live or cured resin as good if not better than indoor crops due to the more complex flavors of being grown outdoors under the full sun spectrum.

Damaged Product (Insect / Physical Damage):

Products that are damaged from aphids mites and animals may not be able to be sold for re-rolls and flower but can retain significant value if used for resin extracts.

Temperature / Smoke Damage:

There isn’t much that can be done other than turning the product into bulk THCA diamonds or bulk distillate. Attempts to turn into pre-rolls or live resin run very high risks of an inferior product and stuck inventory.

Conclusion:

In the cannabis industry, maximizing profitability requires a strategic approach that goes beyond manufacturing efficiency. This article has outlined a farm-to-table perspective on how cannabis companies can extract the best return on investment (ROI) from their crops. From the pinnacle of premium indoor whole-plant cultivation to the cost-effective light-deprivation greenhouses and full-sun outdoor methods, each approach presents unique challenges and opportunities. Salvaging damaged products, whether from insects, physical damage, or environmental factors, highlights the importance of resourcefulness in the cannabis industry. While this article doesn’t cover all the products that can be recombined, ultimately, understanding the nuances of the production process and product recombination is crucial for cannabis businesses aiming to navigate the intricate path to financial success. By leveraging the utility value of each input, from flower to resin, and optimizing manufacturing steps, cannabis companies can position themselves to achieve the best ROI and remain competitive in the market.