Heating highly viscous extracts require speed of heating and precision control to avoid browning discoloration and denaturing terpenes. The article below shows different types of heating equipment used and temperature gradient distributions so lab managers can pick the best technique for their process.

Topics covered are:

- Hotplate visualized

- Water baths visualized

- Warming ovens visualized

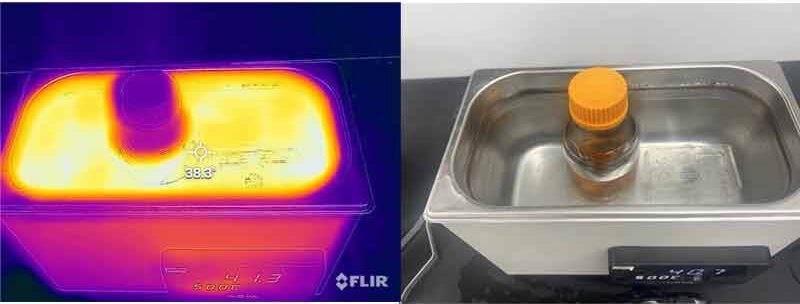

Water baths are the fastest and the safest

Hemp & cannabis extracts are very viscous and heat transfer takes time which is at odds with keeping extract material at the lowest possible temperature possible for preservation. The fastest method is the water bath due to the thermal mass of the water and the gentle nature of heating up the jars. How plate stirrers can be used if the company can tolerate discoloration. Finally, warming ovens can also be used for bulk distillate warm-up but are slower if there is no forced air to even out temperature homogeneity.

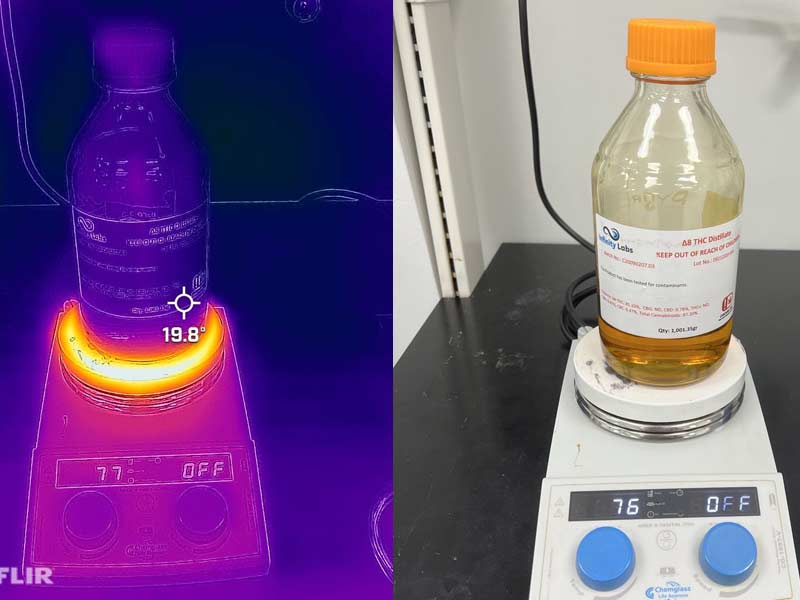

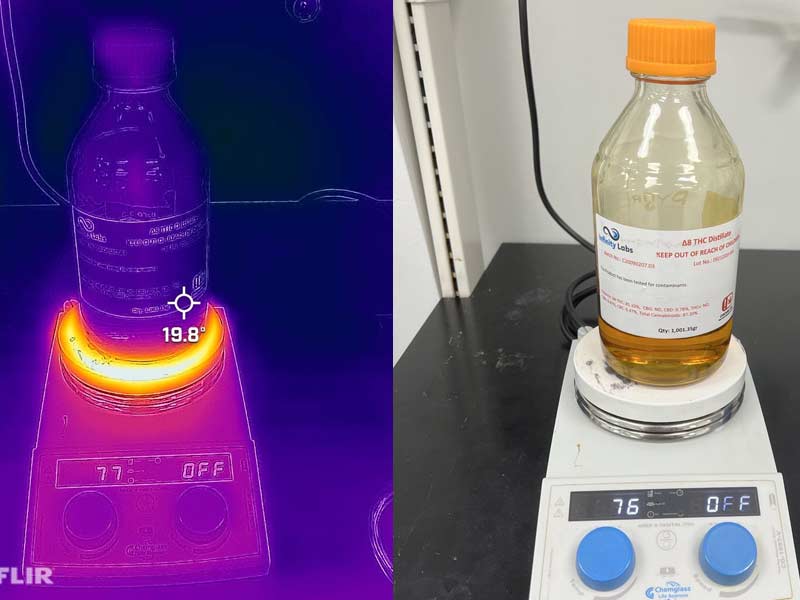

Hotplate visualized

Below is a hotplate stirrer visualized with an infrared camera. Notice the large thermal gradient from hot to cold. This thermal gradient and the lack of contact area slow down extract heating.

Water baths visualized

Below is a water bath visualized with an infrared camera. Notice how the water “wraps” around the bottle distribution to all surfaces of the extract.

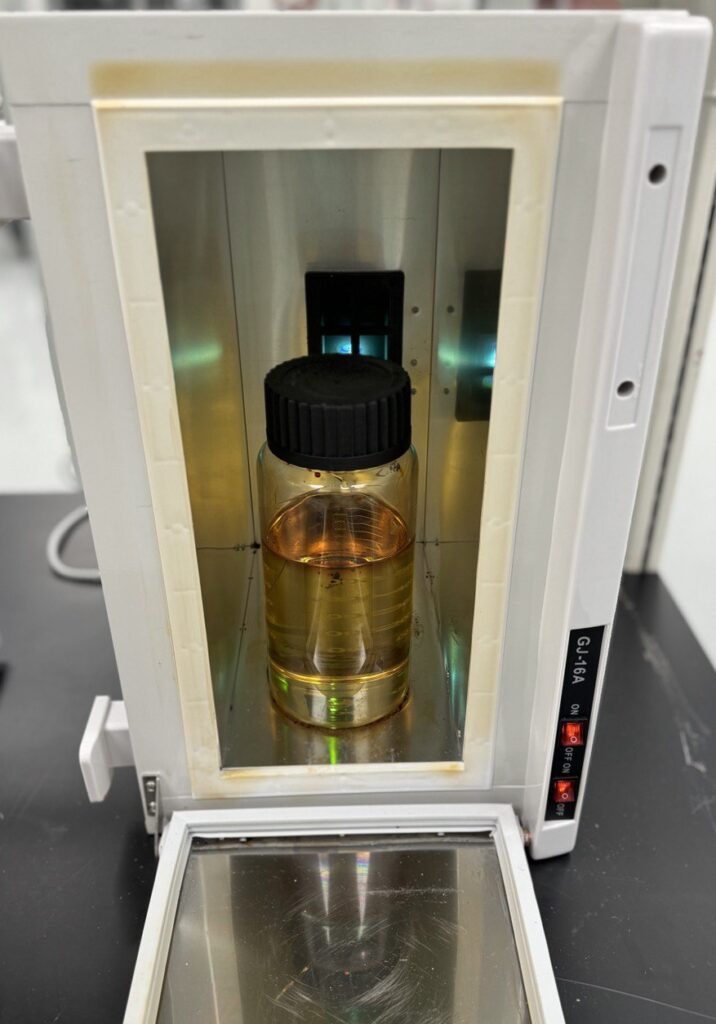

Warming ovens visualized

Below is a warming oven visualized with an infrared camera. Notice the heating surfaces enclose the container.

Closing

Understanding what products provide even heating keeps extracts safe while reducing preparation time.