Color Remediating Distillate

Discover the causes of browning distillate and how to prevent and fix browning and discolored distillate

by Jeff Wu - August 4, 2024

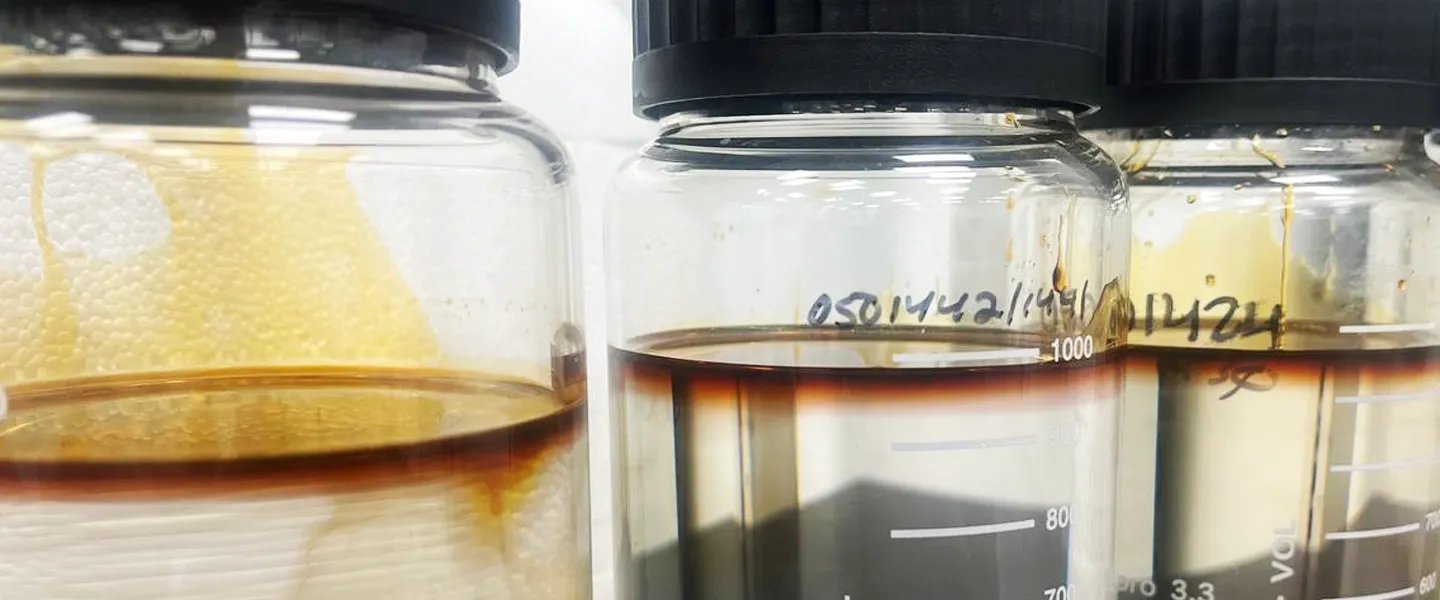

Fixing browning or purpling in distillate.

It is a safe bet that people do not like to vape purple or brown distillate. Browning distillate in vapes costs major brands millions of dollars in damage each year while the fixes are not difficult if executed early enough.

This article outlines how to fix discoloration issues in cannabis resins distillate

What is the root of all cannabis resin (distillate, CBD, D8, etc) discoloration (referred to as “distillate” for simplicity)? Oxidation – when resin reacts to the surrounding oxygen or other compounds in vapes.

What causes distillate discoloration?

During Extraction / Reaction (CBD to THC conversion)

Ethanol Extraction

Using “dirty” ethanol – from lime dust on plants or reusing ethanol without cleaning redistillations and balancing the ph

Ethanol will discolor and appear yellow once pH is off.

BHO Extraction

Boiling the collection pot too long – usually occurs on manual Bizzy Bees when extractor leaves the collection on for too long

Catalyst Conversion (CBD / CBG -> to THC)

Residual catalyst or quenching agent (bicarbonate) is not washed out from mixture

During Mixing, Workup and Storage

Storage – Storing in warm and hot environments. Heat eventually browns distillate and starts degradation reactions

Formulation – Using too much PG

PG turns red when it oxidizes

Unsealed containers – This lets in oxygen

Store in proper sealed containers can prevent oxidative distillate browning

During Mixing/Filling & Transport

Distillate Mixture Warmup

Using hot plates that have hot spots that overheat the bottom layers of distillate

High Filling Temperature

Many CDTs oxidize at 55C and above

Capping Too Slow

This traps an air bubble (filled with oxygen) in the cart which causes oxidation

High Temperature Transport

Hot temperature in distro van – long transport times in hot vans will cause oxidation

How to fix brown & discolored distillate

Option 1: Return to seller for remediation

If distillate is less than $4000.00 per kg, it is simply not cost effective to self remediate. Sending it back to the manufacturer is the easiest and cheapest way to handle this situation. Bulk distillate manufacturers can turn around color remediation within a day or two. While it is possible to self remediate, the equipment needed time and transfer loss usually makes it not worthwhile to do.

Option 2: Over oxidize and formulate with a fruity or dank strain

While controversial, over oxidize the distillate by spread out in a glass pan to trigger fast oxidation reaction (3 days @ room temp or 24hrs in 60Coven). This will brown the material to a stabilized point and create a “oxidized distillate flavor. Use a fruity flavor like grape or something very dank and pungent to mask the distillate.

Option 3: Self remediate

Generally not worth doing, however if you are stuck and/or the supplier that cannot or will not remediate, the general steps are below:

Equipment needed:

2 x 50 or 100 liter reactors with temperature controlled circulators

Falling film evaporators (Rotavapors can be used but are too slow and not cost effective for this purpose)

4–5 large separatory funnels with filter paper

3&4 angstrom molecular sieves – 2 gallons of each

Heptane 2x by volume total amount of distillate

Precision vacuum ovens or warming oven

Carboys to hold in process material

NaCl salt – no iodine

water – distilled

Procedure: (if using 10 liters of distillate)

Melt distillate and dissolve into heptane at 1:2 ratio in a 100 liter reactor heated to 60C – this dissolves distillate into heptane for a total of 30 liters used

Wash step A) Load in 2X volume of tap warm water – this adds 60 liters of water for a total of 90 liters used. turn the stirrer on max and vigorously stir the solution for 30 minutes. Drain water to finish

Repeat wash step with saline solution

Repeat wash step with tap water

Repeat wash step with distilled water

Repeat wash step with distilled water

Prep separatory funnel with 6 inches depth of molecular sieves 3-4 angstroms mixed topped with silica

Pour entire reactor contents (distillate and heptane mix)material through separatory funnel with molecular sieves slowly

Distill heptane out with falling film evaporator

Run distillate through falling film again to remove residual heptane.

The repeated water washes are designed to eject most polar material and ions from the distillate solution. Molecular sieves are to capture any residual ions. Falling films are to efficiently remove heptane and return distillate into a pure form.

Option 4 – Buffer solution with HDTs, CDTs or Live resin terpenes

Live resin sauce, and cannabis derived terpenes (CDTs/HDTs) have many polar compounds and terpenes. Many of these compounds are pH buffers and cancel out pH issues in a distillate solution thereby stopping oxidation and color changes from occurring.

How much CDTs or live resin terpenes is required to stop oxidation? Approximately 2.5% by weight is enough. By buying a neutral CDT and layer the flavor underneath your primary flavors.

Note: This method works if distillate is just starting to oxidize and discolor – if already fully oxidized you will not be able to reverse the color degradation by adding a CDT buffer.

Other process that cause brown distillate vapes

Not backfilling storage containers with Argon or Nitrogen

Backfilling containers with Argon (preferred) or Nitrogen remove O2 will allow for long term storage at room temperatures

Use proper warming equipment

Do not use hot plates – use water baths or precision ovens and go to 55C or less. The hot spots on hot plates cause localized oxidation and ruins the look of the material

Stick with waterbaths or proper lab ovens

Use proper filing equipment

Many fillers run at over 70 C and cause both oxidative brown lines and flavor issues inside the cartridge.

Use a Xylem X4 which runs at low temps plus caps very quickly meaning air will not be trapped in the vape which can trigger oxidation on top of making the vape appear not full. A max fill (without bubbles) preserves looks of the cartridge for months.

Jeff Wu

Technical Director

Investor & entrepreneur, bringing a unique blend of scientific knowledge and hands-on experience in pharma, laboratory, manufacturing, and cannabis. Deep understanding of chemistry, electronics manufacturing, automation, and cannabis processing.