With the emergence of a regulated market in cannabis, the practice of “cutting” or “diluting” concentrates with a cheap additive is still a common practice that is carried over from the black market. This article addresses a few items on inbound extract quality control to find faults in inputs before they make it downstream into the supply chain.

What are the most common cutting agents found in cannabis extracts?

- Propylene glycol – used to cut crude and distillate

- Vegetable Glycerin – used to cut crude and distillate

- MCT Oil – used mostly to cut crude oil

- Mineral Oil – used mostly to cut crude oil

- Butane – used to cut live resin

How can you tell if your concentrate (crude, distillate, live resin) has a cutting agent?

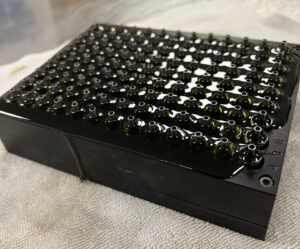

Viscosity at room temperature (75F 25C) is very low. Ethanol extracted crude, and purified distillate is almost solid blocks at room temperature. Live resin is a bit trickier as some resins are runny at room temperature — however, live resin with butane will “bubble” at body (37C) temperature when stirred. A mass spectrometer can identify any material, however, this may not be feasible due to cost and time.

How to identify and test for cutting agents (without the use of a mass spectrometer) for extract quality control:

Propylene Glycol:

What to look for: Material cut with PG tends to turn reddish brown over time if stored for extended periods of time.

PG is soluble in water. Perform an antisolvent extraction with water — PG will immediately wash out into the solution and create a milky white solution.

Vegetable Glycerin:

What to look for: Material cut with VG is noticeably more runny and less viscous.

VG is also soluble in water. Perform an antisolvent extraction with water — VG will immediately flow out into the solution and create streaks in the solution.

MCT Oil:

What to look for: MCT is a stealth cutting agent — having similar density and boiling points to THC and CBD distillate, and being oil soluble, which means water separation and distillation will not work. However, MCT oil is very runny — even a small amount at 5% can have a dramatic impact on viscosity, which will be a dead giveaway on its presence.

Separate MCT by dissolving in ethanol and then winterization @ -80C in a freezer to freeze out MCT oil.

Mineral Oil:

What to look for: Mineral oil is about 20% less dense than distillate meaning it will occupy 20% more volume than distillate of equal weight. It is easy to spot in glass jars that are volume marked, as extracts with mineral oil will suspiciously appear fuller at the same weight.

Mineral oil is easily separated by short path distillation or a thin film wipe system due to its high boiling point of 300C.

Butane:

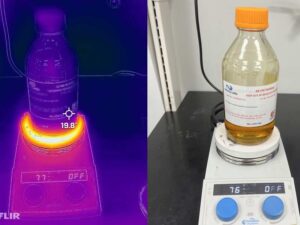

What to look for: Butane has a very low boiling point. Raise the temperature to 45C and watch for bubbles and off-gassing. Bubbles will indicate the presence of butane as liquid live resin once decarboxylated, and should be free of butane. One can also try the flame test which is not recommended.

Butane off-gassing can be performed with a vacuum oven.

Tips and tricks to mitigate for inbound extract quality control personnel:

- Always ask for Certificates of Analysis on every batch — many times it is difficult to fake these results.

- Always perform inbound QC inspection — with multiple batches of product, check for viscosity differences jar-to-jar with a quick shake of the bottle

- Water separation — butane off-gassing quick checks only take minutes to perform on questionable batches of material.