-

Vape Filling

A family of automated vape cart fillers, that provide both cart filling and integrated capping solutions for cartridges and all-in-one vaporizers for companies of all scales.

-

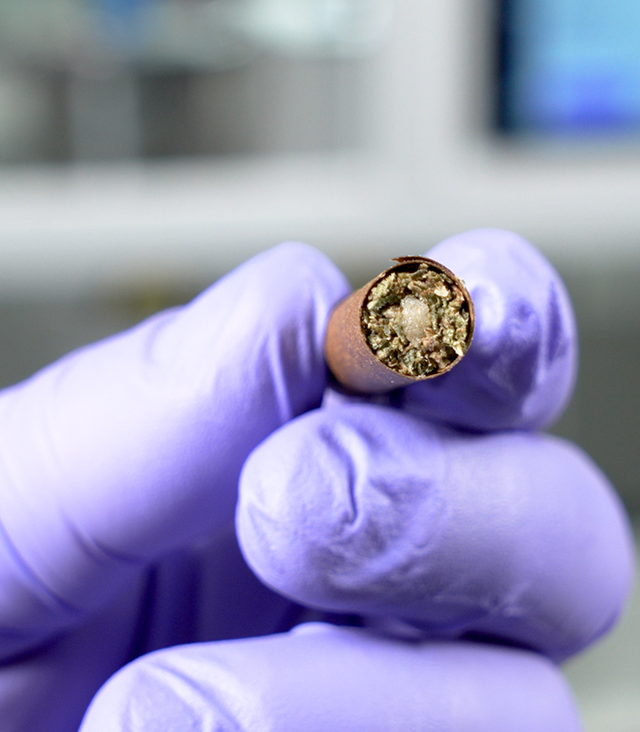

PreRoll Infusion

Force Protection

Automated preroll infusion system, that provides high machine uptime and is compatible across cones, strait prerolls, blunts -- all in a simple and easy to operate platform.

-

Full Production Automation

Full Vape Manufacturing Line

Fully automated filling, cleaning, QC, and packaging all in one line in the fastest, most efficent and lowest cost production method available.

-

Vape Packaging

Automated Cart Packaging Systems

Automated bagging and boxing systems tailor-made for vape carts CRP packaging requirements for high efficency commercial production requirements.

-

Resources

Technical Resources

-

Support

System Support

Xylem offers full-service, commisioning and install of equipment and on site training of operators for next-generation cart fillers.